Filler masterbatches improve the performance and durability of plastic products and provide cost advantages by optimizing production processes.

Types of Filler Masterbatch

Product Types of Filler Masterbatch

What is Masterbatch?

What is Masterbatch?

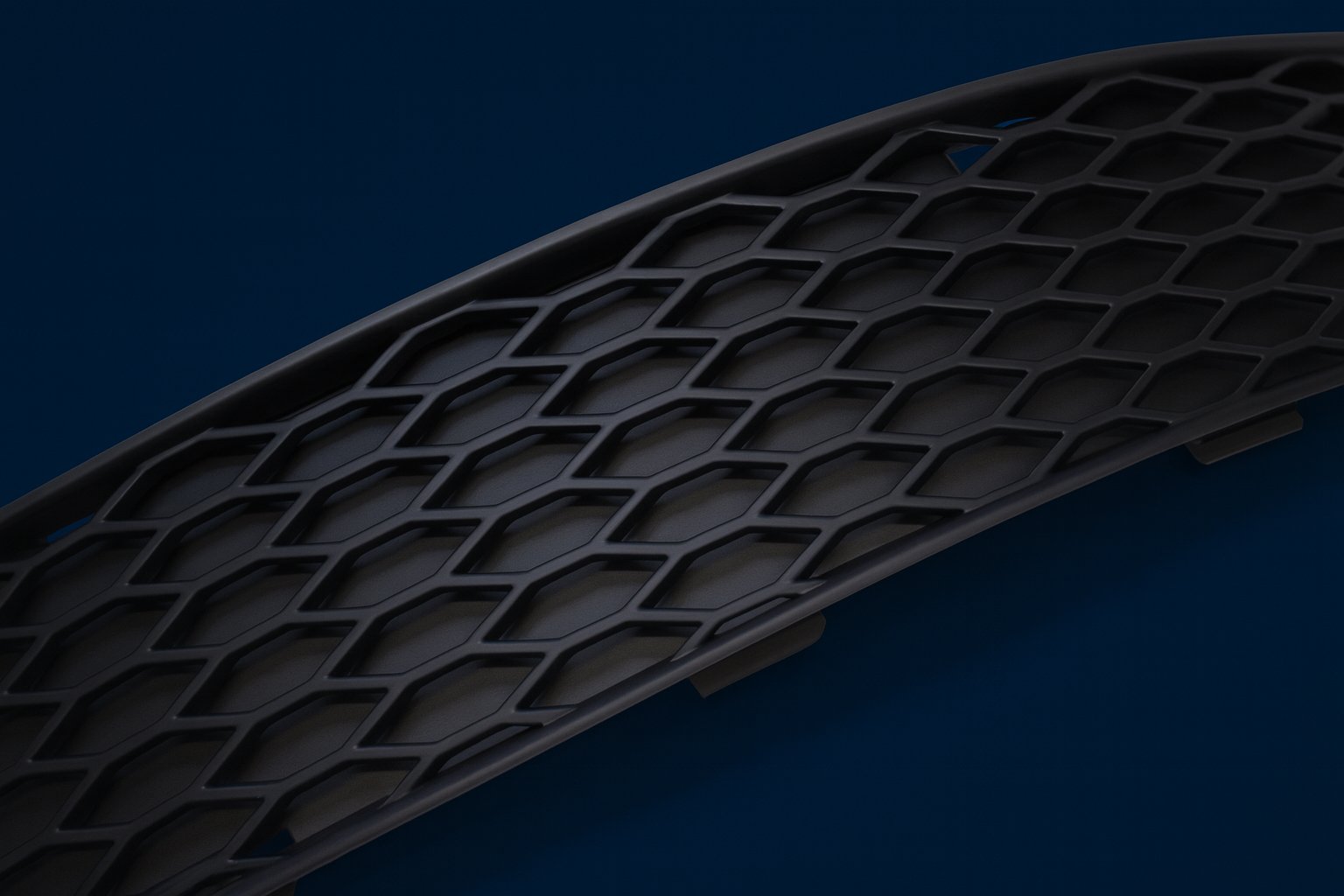

Termoform is a leading manufacturer specializing in high-performance masterbatch solutions, offering a wide portfolio of filler and additive masterbatch products. These granular additives are engineered to enhance the mechanical, visual, and processing properties of plastic materials across various industries.

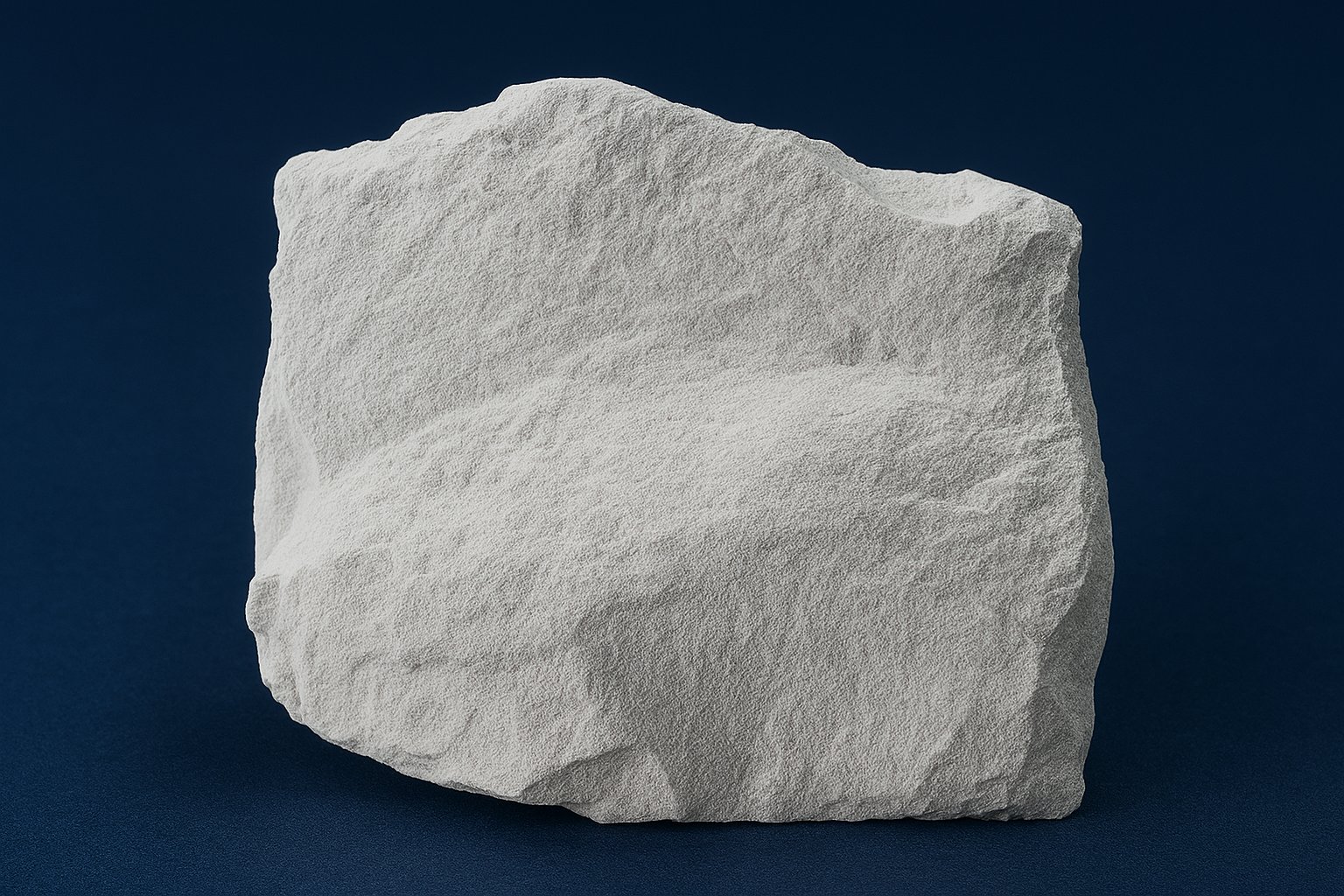

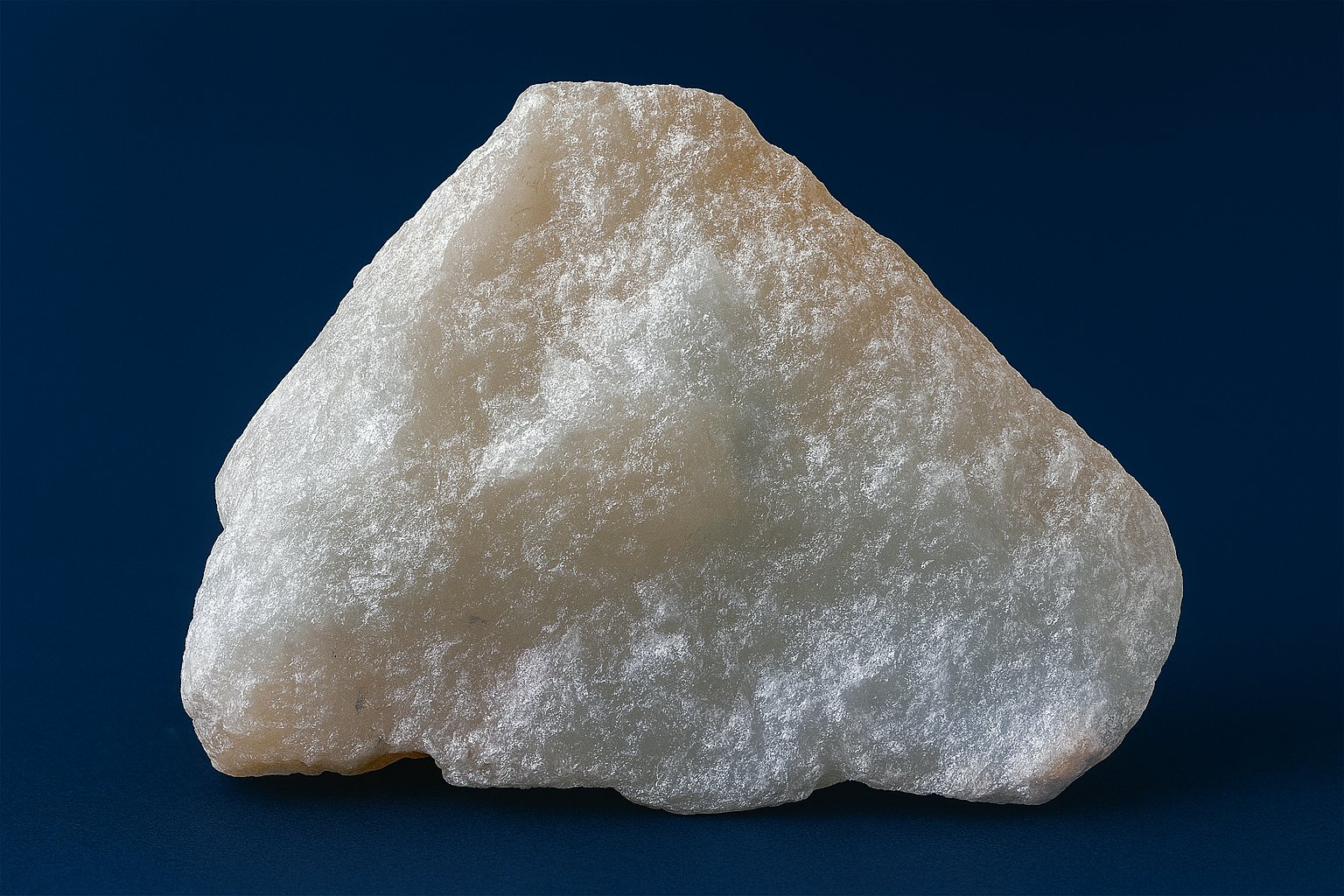

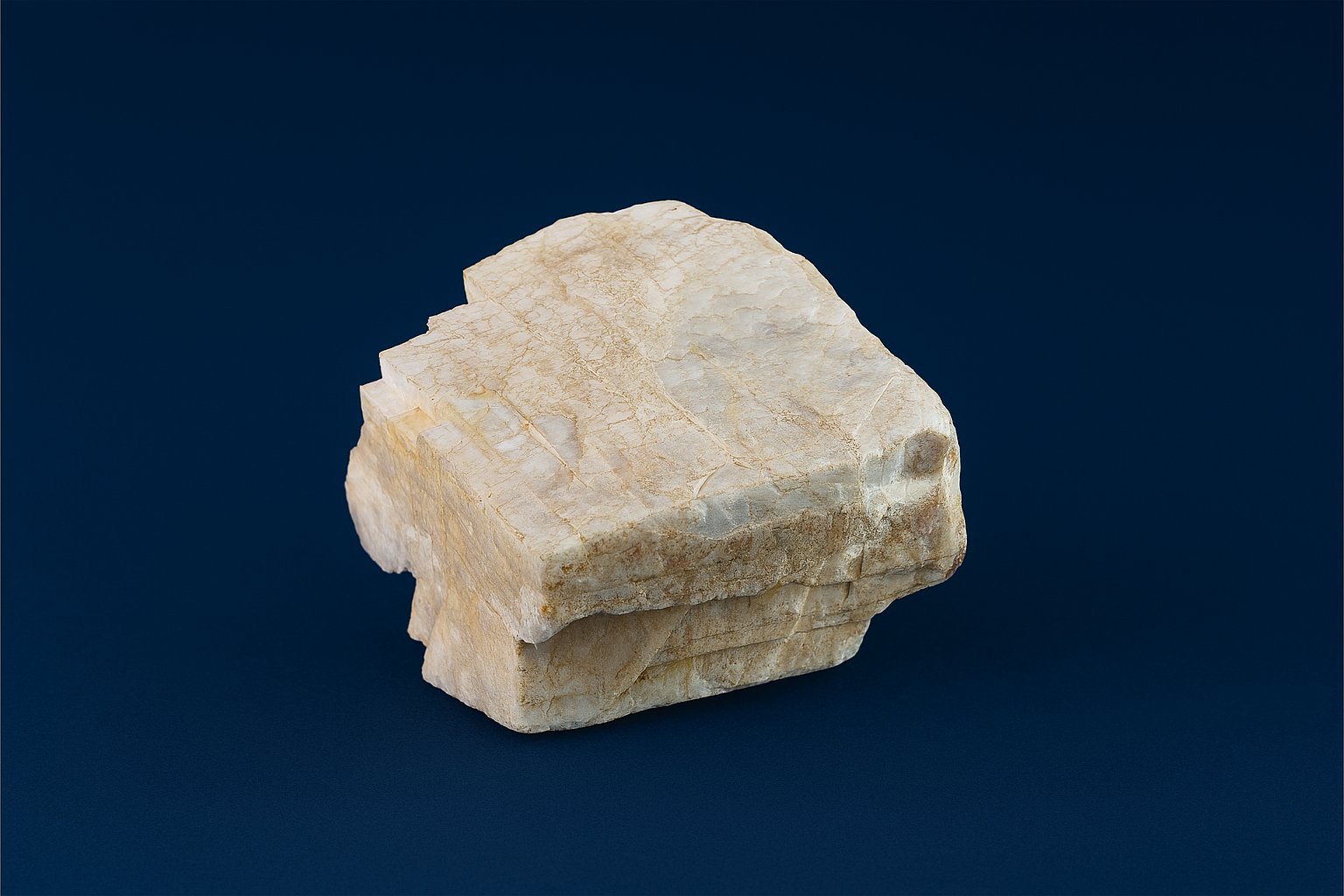

With advanced production lines and a strong commitment to innovation, Termoform produces masterbatches formulated with calcium carbonate (CaCO₃), talc, barite (BaSO₄), fiberglass, and other functional additives. These are carefully blended with carrier polymers such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and ABS, ensuring high compatibility and consistent performance.

Additive Masterbatch is a concentrated additive or pigment in granular form, used during plastic processing to improve features such as strength, printability, UV resistance, thermal stability, color, surface quality, and cost efficiency. By incorporating Termoform masterbatches into their production, manufacturers achieve better processability, material savings, and final product quality in applications including packaging, automotive, construction, household goods, hygiene products, and more.

At Termoform, we shape the future with innovative solutions, combining quality, performance and sustainability in plastics production, offering reliable and high value-added products to each sector.